TMP1200 User Guide

Part 1: Setup

Part 2: Using Your Phidget

About

The TMP1200 allows you to precisely measure temperature using RTDs, thermistors, and other resistance-based sensors. Measure temperature from your RTD in degrees Celsius by selecting the RTD type and the number of wires in the software. You can also read thermistors and other resistive sensors by using the resistance sensor object in your program. You'll receive the data in ohms and can convert to the desired unit by using the formula in your sensor's datasheet. You could even use it as a simple ohmmeter for resistances up to 19 kΩ.

Explore Your Phidget Channels Using The Control Panel

You can use your Control Panel to explore your Phidget's channels.

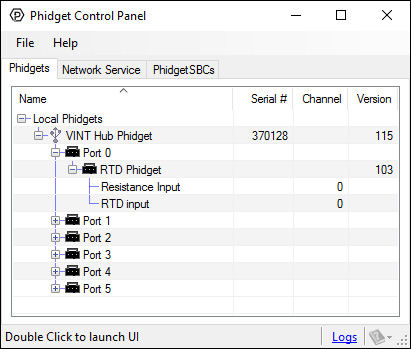

1. Open your Control Panel, and you will find the following channels:

2. Double click on a channel to open an example program. Each channel belongs to a different channel class:

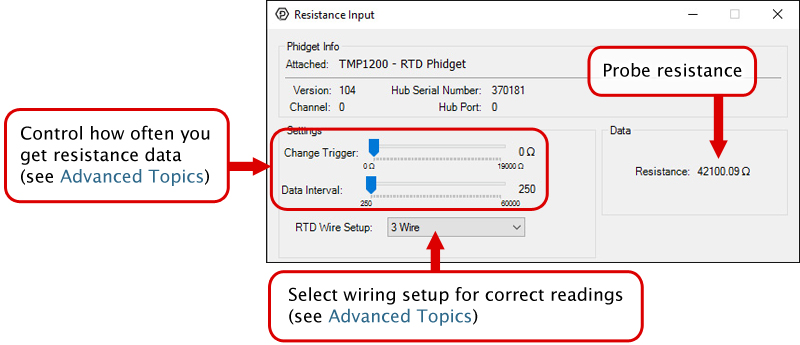

In your Control Panel, double click on "Resistance Input":

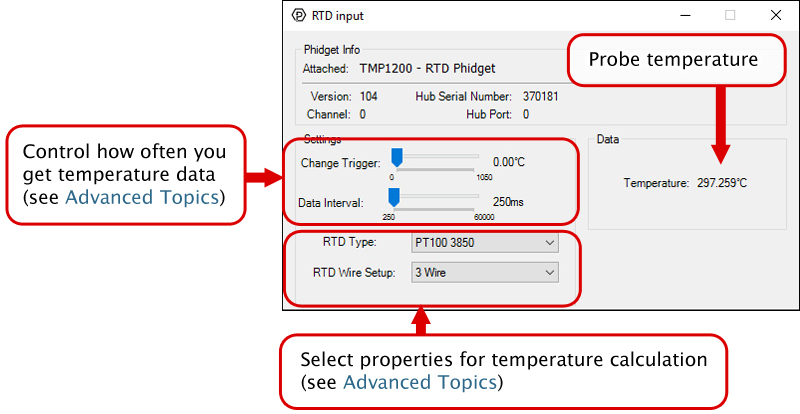

In your Control Panel, double click on "RTD Input":

Part 3: Create your Program

Part 4: Advanced Topics and Troubleshooting

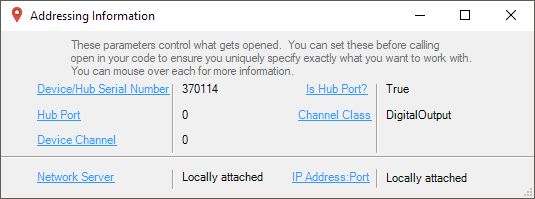

Before you open a Phidget channel in your program, you can set these properties to specify which channel to open. You can find this information through the Control Panel.

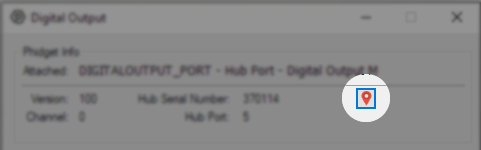

1. Open the Control Panel and double-click on the red map pin icon:

2. The Addressing Information window will open. Here you will find all the information you need to address your Phidget in your program.

See the Phidget22 API for your language to determine exact syntax for each property.

The Change Trigger is the minimum change in the sensor data needed to trigger a new data event.

The Data Interval is the time (in ms) between data events sent out from your Phidget.

The Data Rate is the reciprocal of Data Interval (measured in Hz), and setting it will set the reciprocal value for Data Interval and vice-versa.

You can modify one or both of these values to achieve different data outputs. You can learn more about these properties here.

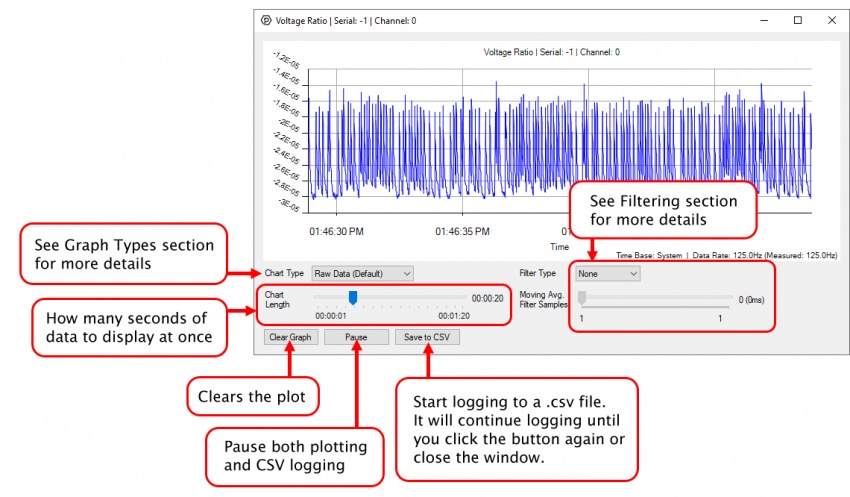

Note: Graphing and logging is currently only supported in the Windows version of the Phidget Control Panel.

In the Phidget Control Panel, open the channel for your device and click on the ![]() icon next to the data type that you want to plot. This will open up a new window:

icon next to the data type that you want to plot. This will open up a new window:

If you need more complex functionality such as logging multiple sensors to the same sheet or performing calculations on the data, you'll need to write your own program. Generally this will involve addressing the correct channel, opening it, and then creating an Event Handler and adding graphing/logging code to it.

The quickest way to get started is to download some sample code for your desired programming language and then search google for logging or plotting in that language (e.g. "how to log to csv in python") and add the code to the existing change handler.

Filtering

You can perform filtering on the raw data in order to reduce noise in your graph. For more information, see the Control Panel Graphing page.

Graph Type

You can perform a transform on the incoming data to get different graph types that may provide insights into your sensor data. For more information on how to use these graph types, see the Control Panel Graphing page.

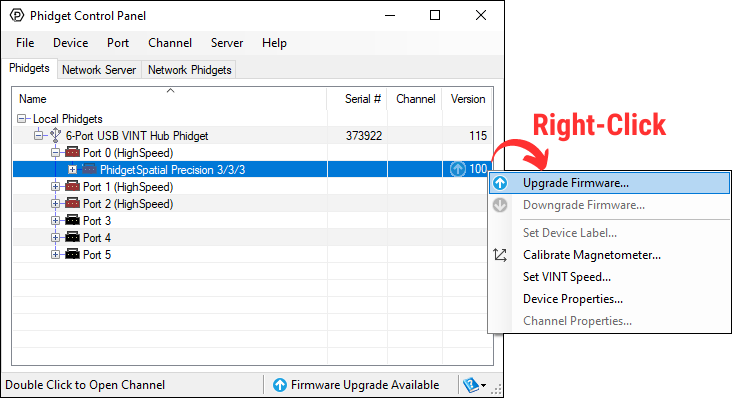

Firmware Upgrade

MacOS users can upgrade device firmware by double-clicking the device row in the Phidget Control Panel.

Linux users can upgrade via the phidget22admin tool (see included readme for instructions).

Windows users can upgrade the firmware for this device using the Phidget Control Panel as shown below.

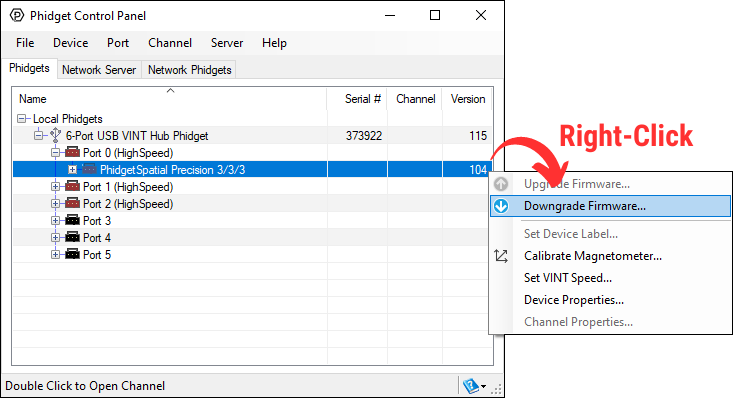

Firmware Downgrade

Firmware upgrades include important bug fixes and performance improvements, but there are some situations where you may want to revert to an old version of the firmware (for instance, when an application you're using is compiled using an older version of phidget22 that doesn't recognize the new firmware).

MacOS and Linux users can downgrade using the phidget22admin tool in the terminal (see included readme for instructions).

Windows users can downgrade directly from the Phidget Control Panel if they have driver version 1.9.20220112 or newer:

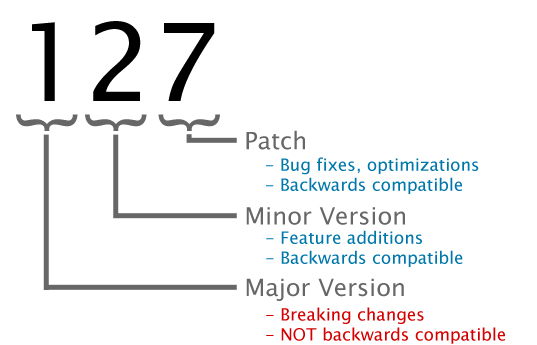

Firmware Version Numbering Schema

Phidgets device firmware is represented by a 3-digit number. For firmware patch notes, see the device history section on the Specifications tab on your device's product page.

- If the digit in the 'ones' spot changes, it means there have been bug fixes or optimizations. Sometimes these changes can drastically improve the performance of the device, so you should still upgrade whenever possible. These upgrades are backwards compatible, meaning you can still use this Phidget on a computer that has Phidget22 drivers from before this firmware upgrade was released.

- If the digit in the 'tens' spot changes, it means some features were added (e.g. new API commands or events). These upgrades are also backwards compatible, in the sense that computers running old Phidget22 drivers will still be able to use the device, but they will not be able to use any of the new features this version added.

- If the digit in the 'hundreds' spot changes, it means a major change has occurred (e.g. a complete rewrite of the firmware or moving to a new architecture). These changes are not backwards compatible, so if you try to use the upgraded board on a computer with old Phidget22 drivers, it will show up as unsupported in the Control Panel and any applications build using the old libraries won't recognize it either. Sometimes, when a Phidget has a new hardware revision (e.g. 1018_2 -> 1018_3), the firmware version's hundreds digit will change because entirely new firmware was needed (usually because a change in the processor). In this case, older hardware revisions won't be able to be upgraded to the higher version number and instead continue to get bug fixes within the same major revision.

If your device has a ![]() icon printed on the enclosure, it means that it has an improved filter on its VINT connection that upgrades performance when plugged into a port on a VINT Hub that also has the

icon printed on the enclosure, it means that it has an improved filter on its VINT connection that upgrades performance when plugged into a port on a VINT Hub that also has the ![]() icon:

icon:

- Improved immunity to electromagnetic interference from other nearby electronics

- Increased maximum Phidget Cable length

For details on how the maximum cable length is impacted, see the specifications tab on the product page for this device.

Two-Wire Mode

This is the simplest wiring setup for an RTD, but also the least accurate because the resistance of the leads are not taken into account. To connect a 2-wire RTD to the RTD Phidget, connect one wire to the RTD+ terminal, and the other to the RTD- terminal. Then connect the EXC+ terminal to the RTD+ terminal and the EXC- to the RTD- terminal with two short wires.

In your program, set RTDWireSetup to 2-wire mode. In the Phidget22 API select the TMP1200 and your programming language of choice to see exact naming conventions.

Three-Wire Mode

In a three-wire RTD, the extra wire is added to measure the resistance of one of the leads. This calculation assumes that both leads have the same resistance. Your RTD should have two wires that share a color; connect one of these wires to the RTD- terminal and the other to the EXC- terminal. The differently colored wire connects to the RTD+ terminal. Then connect the EXC+ terminal to the RTD+ terminal with a short wire.

In your program, set RTDWireSetup to 3-wire mode. In the Phidget22 API select the TMP1200 and your programming language of choice to see exact naming conventions.

Four-Wire Mode

A four-wire RTD is normally used in precision measurement, when the assumption that both leads have the same resistance is not accurate enough. Unfortunately the RTD Phidget does not support this particular feature of four-wire RTDs. It does support the use of four-wire RTDs using the same assumption as three-wire mode. To connect a four-wire RTD, simply connect one pair of same-colored wires to the RTD+ and EXC+ terminals, and the other pair to the RTD- and EXC- terminals.

In your program, set RTDWireSetup to 4-wire mode. In the Phidget22 API select the TMP1200 and your programming language of choice to see exact naming conventions.

In three and four wire modes, this device will measure the line resistance every 5 minutes. This measurement will cause a delay in measurement for data intervals of less than 500ms. To force the line resistance to be recalculated, you must close and re-open the device.