TMP1101 User Guide

Part 1: Setup

Part 2: Using Your Phidget

About

The TMP1100 allows you to measure extreme temperatures with up to 4 thermocouples. This Phidget connects to a J, K, E, or T type thermocouple. Choose the thermocouple type in software and data will be converted to degrees Celsius automatically. If you have other thermocouple types, you can open the channel in VoltageInput mode and convert it to Celsius manually.

Explore Your Phidget Channels Using The Control Panel

You can use your Control Panel to explore your Phidget's channels.

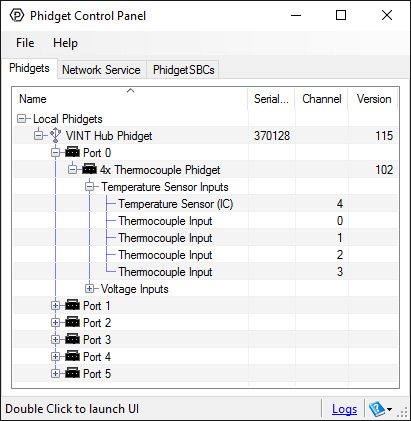

1. Open your Control Panel, and you will find the following channels:

2. Double click on a channel to open an example program.

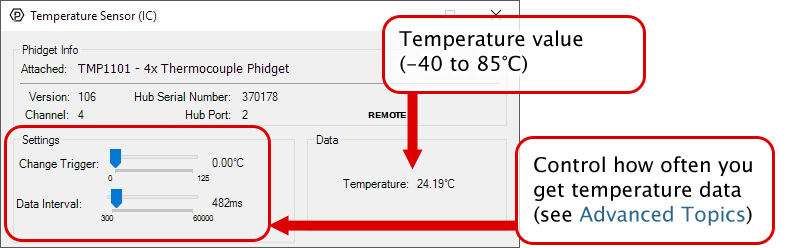

In your Control Panel, double click on "Temperature Sensor (IC)":

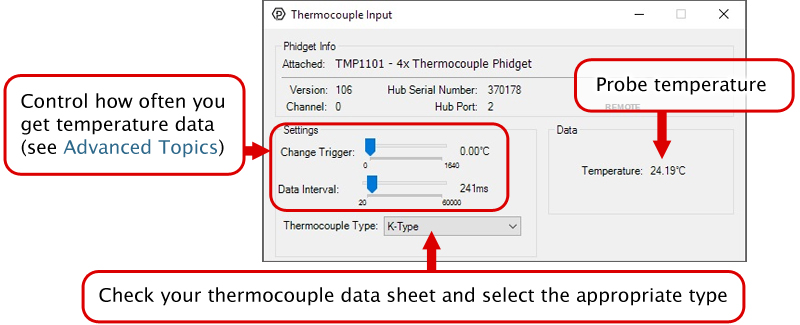

In your Control Panel, double click on "Thermocouple Input":

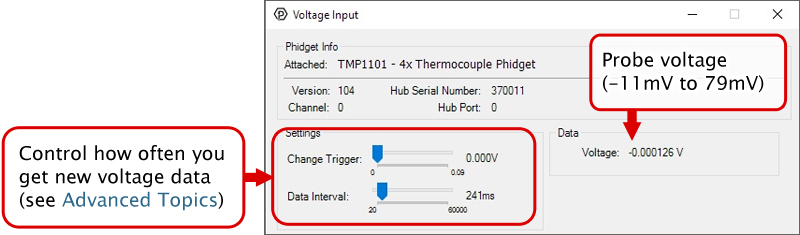

In your Control Panel, double click on "Voltage Input":

Part 3: Create your Program

Part 4: Advanced Topics and Troubleshooting

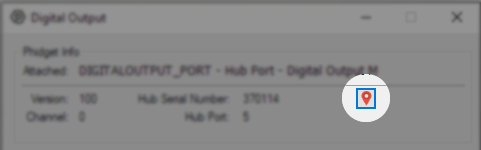

Before you open a Phidget channel in your program, you can set these properties to specify which channel to open. You can find this information through the Control Panel.

1. Open the Control Panel and double-click on the red map pin icon:

2. The Addressing Information window will open. Here you will find all the information you need to address your Phidget in your program.

See the Phidget22 API for your language to determine exact syntax for each property.

The Change Trigger is the minimum change in the sensor data needed to trigger a new data event.

The Data Interval is the time (in ms) between data events sent out from your Phidget.

The Data Rate is the reciprocal of Data Interval (measured in Hz), and setting it will set the reciprocal value for Data Interval and vice-versa.

You can modify one or both of these values to achieve different data outputs. You can learn more about these properties here.

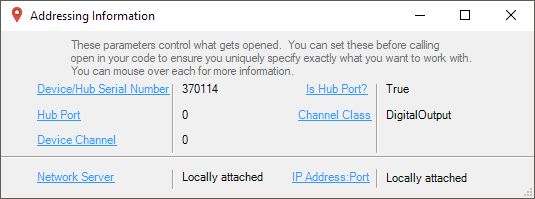

Note: Graphing and logging is currently only supported in the Windows version of the Phidget Control Panel.

In the Phidget Control Panel, open the channel for your device and click on the ![]() icon next to the data type that you want to plot. This will open up a new window:

icon next to the data type that you want to plot. This will open up a new window:

If you need more complex functionality such as logging multiple sensors to the same sheet or performing calculations on the data, you'll need to write your own program. Generally this will involve addressing the correct channel, opening it, and then creating an Event Handler and adding graphing/logging code to it.

The quickest way to get started is to download some sample code for your desired programming language and then search google for logging or plotting in that language (e.g. "how to log to csv in python") and add the code to the existing change handler.

Filtering

You can perform filtering on the raw data in order to reduce noise in your graph. For more information, see the Control Panel Graphing page.

Graph Type

You can perform a transform on the incoming data to get different graph types that may provide insights into your sensor data. For more information on how to use these graph types, see the Control Panel Graphing page.

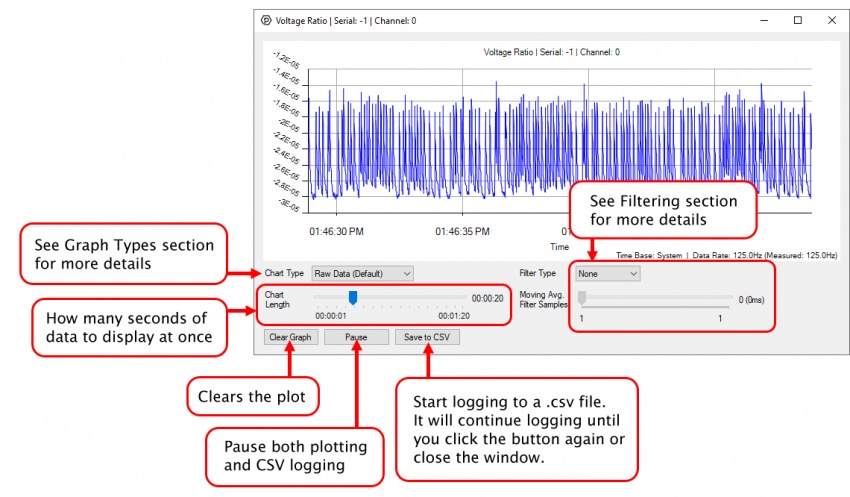

Firmware Upgrade

MacOS users can upgrade device firmware by double-clicking the device row in the Phidget Control Panel.

Linux users can upgrade via the phidget22admin tool (see included readme for instructions).

Windows users can upgrade the firmware for this device using the Phidget Control Panel as shown below.

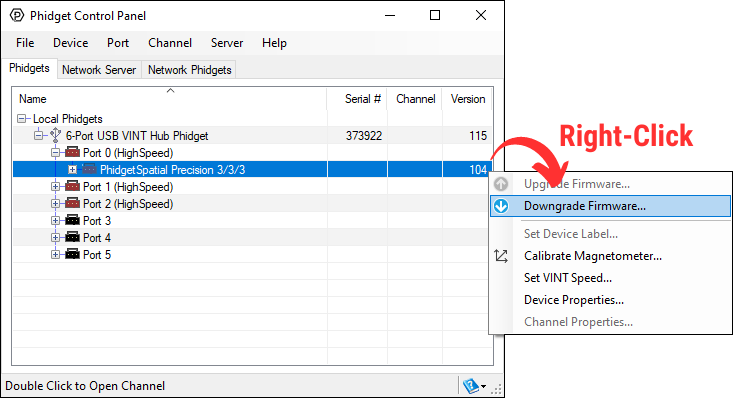

Firmware Downgrade

Firmware upgrades include important bug fixes and performance improvements, but there are some situations where you may want to revert to an old version of the firmware (for instance, when an application you're using is compiled using an older version of phidget22 that doesn't recognize the new firmware).

MacOS and Linux users can downgrade using the phidget22admin tool in the terminal (see included readme for instructions).

Windows users can downgrade directly from the Phidget Control Panel if they have driver version 1.9.20220112 or newer:

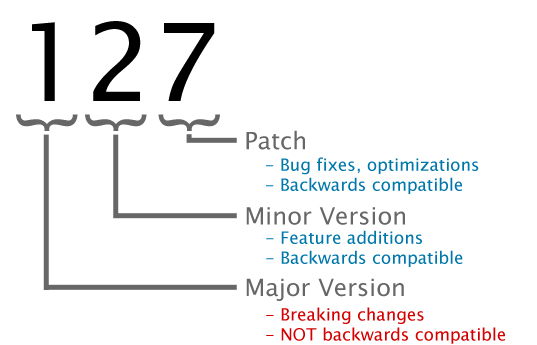

Firmware Version Numbering Schema

Phidgets device firmware is represented by a 3-digit number. For firmware patch notes, see the device history section on the Specifications tab on your device's product page.

- If the digit in the 'ones' spot changes, it means there have been bug fixes or optimizations. Sometimes these changes can drastically improve the performance of the device, so you should still upgrade whenever possible. These upgrades are backwards compatible, meaning you can still use this Phidget on a computer that has Phidget22 drivers from before this firmware upgrade was released.

- If the digit in the 'tens' spot changes, it means some features were added (e.g. new API commands or events). These upgrades are also backwards compatible, in the sense that computers running old Phidget22 drivers will still be able to use the device, but they will not be able to use any of the new features this version added.

- If the digit in the 'hundreds' spot changes, it means a major change has occurred (e.g. a complete rewrite of the firmware or moving to a new architecture). These changes are not backwards compatible, so if you try to use the upgraded board on a computer with old Phidget22 drivers, it will show up as unsupported in the Control Panel and any applications build using the old libraries won't recognize it either. Sometimes, when a Phidget has a new hardware revision (e.g. 1018_2 -> 1018_3), the firmware version's hundreds digit will change because entirely new firmware was needed (usually because a change in the processor). In this case, older hardware revisions won't be able to be upgraded to the higher version number and instead continue to get bug fixes within the same major revision.

Thermocouples consist of two junctions, one where the thermocouple meets the Phidget and one where the two wires are welded together at the sensing end of the device. In simplified terms, a thermocouple works by detecting the temperature difference between these two junctions. To measure the temperature at the sensing end we need to know the temperature where the thermocouple connects to the Phidget. There is an ambient temperature sensor on the board. The thermocouple reading is automatically calculated using the data from the on board temperature sensor.

An important thing to note is that the ambient temperature sensor measures the temperature of the board and the air around it, though not specifically at the junction. Generally you can assume they are nearly the same temperature, however as the electronics heat up by being powered on there can be some small error introduced. This is exacerbated by having the board in an enclosed space where normal airflow is restricted thereby increasing the effect of self-heating. As a result we recommend that the board be left in as open and well ventilated/cooled a place as possible to minimize this error source.

For more information on thermocouples, check out the Thermocouple Guide.

One of the most common sources of electrical noise in a system is 50Hz or 60Hz hum from the local power grid. For firmware versions 107 and later for this Phidget, we have added a filter to compensate for 50Hz or 60Hz hum in your system.

Without filtering, sensors in electrically noisy environments could see a repeating drift of tens of degrees, as noise from power lines finds its way into the system. The timing of this drift could vary, depending on how the samples from the sensor lined up with the noise from the power lines.

To combat this issue, all thermocouple temperature and voltage measurements on this device are now passed through a 100ms moving average filter, with samples taken at specific intervals designed to cancel out frequencies of 50Hz and 60Hz (the most common power grid frequencies). The filtering on this Phidget will reduce the effect of power line noise by 95% or more, becoming more effective as the power line frequency approaches 50Hz or 60Hz exactly.

All samples from the sensor will be subject to filtering. When used with data intervals longer than 100ms, the sensor will measure the thermocouple(s) for 100ms to perform a measurement. When using data intervals less than 100ms, your application will see the effects of the latest measurements as they pass through the filter.