|

Notice: This page contains information for the legacy Phidget21 Library. Phidget21 is out of support. Bugfixes may be considered on a case by case basis. Phidget21 does not support VINT Phidgets, or new USB Phidgets released after 2020. We maintain a selection of legacy devices for sale that are supported in Phidget21. We recommend that new projects be developed against the Phidget22 Library.

|

1120 User Guide

| |

| Go to this device's product page |

Getting Started

Checking the Contents

|

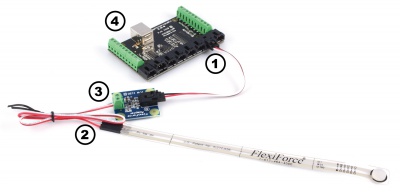

You should have received:

|

In order to test your new Phidget you will also need:

| |

Connecting the Pieces

|

| |

Testing Using Windows 2000 / XP / Vista / 7

Make sure you have the current version of the Phidget library installed on your PC. If you don't, follow these steps:

- Go to the Quick Downloads section on the Windows page

- Download and run the Phidget21 Installer (32-bit, or 64-bit, depending on your system)

- You should see the

icon on the right hand corner of the Task Bar.

icon on the right hand corner of the Task Bar.

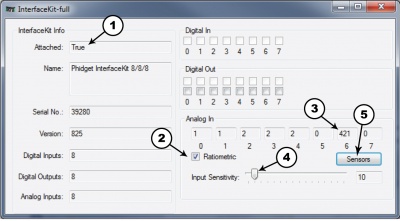

Running Phidgets Sample Program

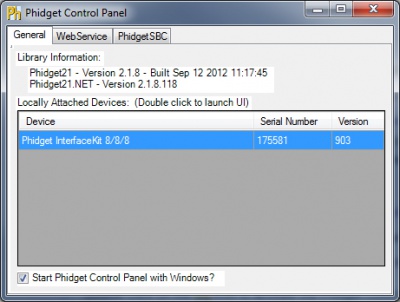

Double clicking on the ![]() icon loads the Phidget Control Panel; we will use this program to ensure that your new Phidget works properly.

icon loads the Phidget Control Panel; we will use this program to ensure that your new Phidget works properly.

The source code for the InterfaceKit-full sample program can be found in the quick downloads section on the C# Language Page. If you'd like to see examples in other languages, you can visit our Languages page.

Updating Device Firmware

If an entry in this list is red, it means the firmware for that device is out of date. Double click on the entry to be given the option of updating the firmware. If you choose not to update the firmware, you can still run the example for that device after refusing.

|

Double Click on the |

| |

|

| |

|

|

Testing Using Mac OS X

- Go to the Quick Downloads section on the Mac OS X page

- Download and run the Phidget OS X Installer

- Click on System Preferences >> Phidgets (under Other) to activate the Preference Pane

- Make sure that the is properly attached.

- Double Click on in the Phidget Preference Pane to bring up the Sample program. This program will function in a similar way as the Windows version.

Using Linux

For a step-by-step guide on getting Phidgets running on Linux, check the Linux page.

Using Windows Mobile / CE 5.0 / CE 6.0

For a step-by-step guide on getting Phidgets running on Windows CE, check the Windows CE page.

Technical Details

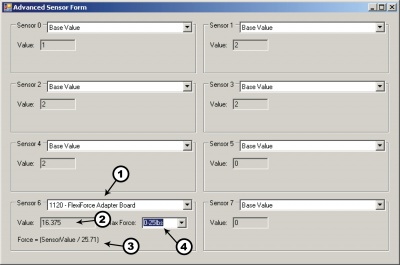

Formulas

The FlexiForce Force sensor is a piezoresistor that has a very large resistance when it is not loaded (in the range of MegaOhms). The resistance decreases as more and more force is applied to it. Tekscan offers sensors with standard force ranges, such as 0-1 lb, 0-25 lbs, and 0-100 lbs. The same adapter board can be used for all three ranges. Because the expected part-to-part variance between FlexiForce sensors is as high as 40%, it is imperative that you calibrate your sensor and determine the specific formula which applies to your sensor. For information on how to calibrate your sensor, refer to the FlexiForce User Manual from Tekscan.

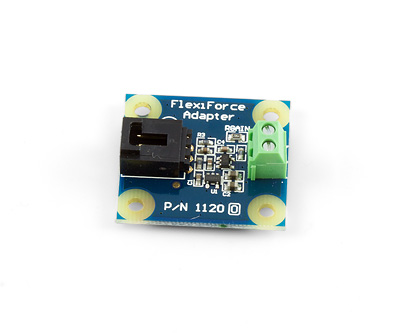

FlexiForce Sensors

The FlexiForce sensors are easy to interface to the adapter board. They can be plugged into the Interface cable that is included. The other end of the cable has been stripped and tinned so that they can be easily inserted into the terminal block. This is useful if a longer cable is needed, as wires can be soldered to the stripped ends. The polarity of the FlexiForce sensors does not matter. If a larger force range is desired, a resistor on the Adapter board can be replaced. This resistor is designated as RGAIN on the board and has a default value of 15 kiloOhms. When the RGAIN resistor value is reduced, the sensor becomes less sensitive and more force can be applied before saturating the output. Conversely, if the RGAIN value is increased, the sensitivity increases and the output saturates at a lower applied force. If RGAIN is changed, calibration with known forces will have to be done to determine the proper formula. Based on limited testing, RGAIN=5 kilo-ohms will give enough range to measure up to 1000 lbs with the 100 lb. Flexiforce sensor. Changing the gain by much larger amounts can cause sensor instability and is not recommended. Also note that adjusting the gain is not a substitute for calibrating and conditioning the sensor. You should look at the manual for the sensor you are using and follow all calibration procedures contained therein before resorting to adjusting the gain value to achieve accurate results.

Measurement Accuracy

To obtain the most accurate results, it is recommended that the sensor rests on a smooth surface and the object is only on the sensing pad and centered as much as possible. This can be achieved by using a small disc (included) that is just large enough to cover the sensing pad, and then placing the full force on the disc. Without the disc, the object may rest on the surrounding surface and record the force inaccurately. Care must also be taken to avoid jagged or sharp edges on the sensing pad, as it can affect the measurement as well as potentially puncture the pad. The pad at the end of the strip is the only place where force is sensed. Any force along the rest of the strip is ignored. The longer the object rests on the sensing pad, the more the SensorValue will drift and vary slowly in value. It is very difficult to compensate for the drift since different constant forces will produce different drift rates. For this reason, the average accuracy of this sensor is approximately 5%. The formula above was determined after the object of known force was resting on the sensing pad for 15 seconds.

Other Interfacing Alternatives

If you want maximum accuracy, you can use the RawSensorValue property from the PhidgetInterfaceKit. To adjust a formula, substitute (SensorValue) with (RawSensorValue / 4.095) If the sensor is being interfaced to your own Analog to Digital Converter and not a Phidget device, our formulas can be modified by replacing (SensorValue) with (Vin * 200). It is important to consider the voltage reference and input voltage range of your ADC for full accuracy and range.

|

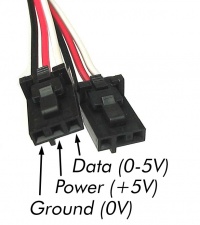

Each Analog Input uses a 3-pin, 0.100 inch pitch locking connector. Pictured here is a plug with the connections labelled. The connectors are commonly available - refer to the Analog Input Primer for manufacturer part numbers. |

| |

API

Phidget analog sensors do not have their own API- they simply output a voltage that is converted to a digital value and accessed through the "Sensor" properties and events on the PhidgetInterfaceKit API. It is not possible to programmatically identify which sensor is attached to the Analog Input. To an InterfaceKit, every sensor looks the same. Your application will need to apply formulas from this manual to the SensorValue (an integer that ranges from 0 to 1000) to convert it into the units of the quantity being measured. For example, this is how you would use a temperature sensor in a C# program:

// set up the interfacekit object

InterfaceKit IFK = new InterfaceKit();

// link the new interfacekit object to the connected board

IFK.open("localhost", 5001);

// Get sensorvalue from analog input zero

int sensorvalue = IFK.sensors[0].Value;

// Convert sensorvalue into temperature in degrees Celsius

double roomtemp = Math.Round(((sensorvalue * 0.22222) - 61.11), 1);

See the PhidgetInterfaceKit User Guide for more information on the API and a description of our architecture.

For more code samples, find your preferred language on the Languages page.

Product History

| Date | Board Revision | Device Version | Comment |

|---|---|---|---|

| February 2010 | 0 | N/A | Product Release |