1131 User Guide

Getting Started

Welcome to the 1131 user guide! In order to get started, make sure you have the following hardware on hand:

- 1131 - Thin Force Sensor

- Any Phidget with a Voltage Ratio Input port, here are some compatible products. We will be using the VINT Hub for this guide.

- USB cable and computer

- Phidget cable

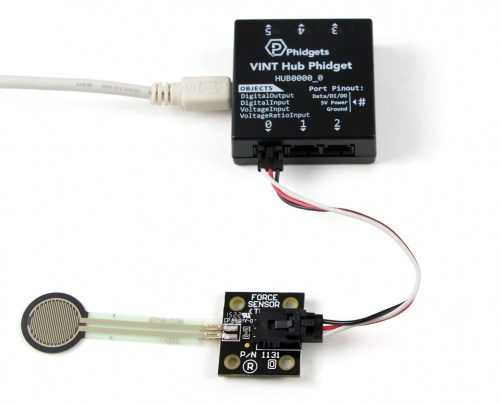

Next, you will need to connect the pieces:

- Connect the 1131 to the HUB0000 with the Phidget cable.

- Connect the HUB0000 to your computer with the USB cable.

Now that you have everything together, let's start using the 1131!

Using the 1131

Phidget Control Panel

In order to demonstrate the functionality of the 1131, we will connect it to the HUB0000, and then run an example using the Phidget Control Panel on a Windows machine.

The Phidget Control Panel is available for use on both macOS and Windows machines. If you would like to follow along, first take a look at the getting started guide for your operating system:

Linux users can follow the getting started with Linux guide and continue reading here for more information about the 1131.

First Look

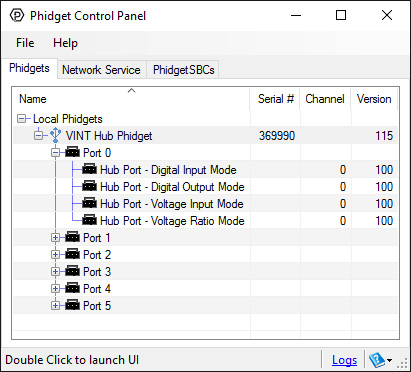

After plugging in the 1131 into the HUB0000, and the HUB0000 into your computer, open the Phidget Control Panel. You will see something like this:

The Phidget Control Panel will list all connected Phidgets and associated objects, as well as the following information:

- Serial number: allows you to differentiate between similar Phidgets.

- Channel: allows you to differentiate between similar objects on a Phidget.

- Version number: corresponds to the firmware version your Phidget is running. If your Phidget is listed in red, your firmware is out of date. Update the firmware by double-clicking the entry.

The Phidget Control Panel can also be used to test your device. Double-clicking on an object will open an example.

Voltage Ratio Input

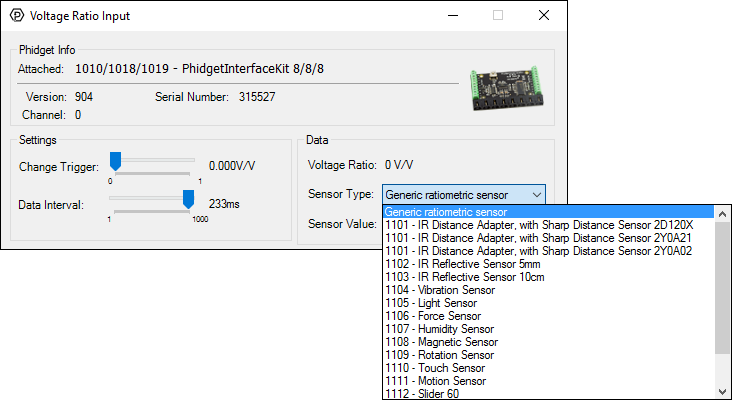

Double-click on a Voltage Ratio Input object in order to run the example:

General information about the selected object will be displayed at the top of the window. You can also experiment with the following functionality:

- Modify the change trigger and/or data interval value by dragging the sliders. For more information on these settings, see the data interval/change trigger page.

- Select the 1131 from the Sensor Type drop-down menu. The example will now convert the voltage into force (grams) automatically. Converting the voltage to force (grams) is not specific to this example, it is handled by the Phidget libraries, with functions you have access to when you begin developing!

Technical Details

General

The 1131 can handle applied forces of up to 2kg.

Formulas

The Phidget libraries can automatically convert sensor voltage into force (grams) by selecting the appropriate SensorType. See the Phidget22 API for more details.The Formula to translate voltage ratio from the sensor into a force in grams is:

Measurement Accuracy

To ensure the most accuracy, a small disc (included) can be placed directly on the sensing pad before applying force to the disc. This will ensure that all the force is applied directly to the sensing pad and not to the surrounding surface. The longer the object rests on the sensing pad, the more the voltage will drift and increase slowly in value. It is very difficult to compensate for the drift since different constant forces will produce different drift rates. For this reason, the average accuracy of this sensor is within 10% of the true value. The formula above was determined after the object with a known mass was resting on the sensing pad for 15 seconds. The general drift rate curve is logarithmic with time.

Set up a Repeatable and Reproducible Mechanical Actuation System

- Provide a consistent force distribution. FSR response is very sensitive to the distribution of the applied force. In general, this precludes the use of dead weights for characterization since exact duplication of the weight distribution is rarely repeatable cycle-to-cycle. A consistent weight (force) distribution is more difficult to achieve than merely obtaining a consistent total applied weight (force). As long as the distribution is the same cycle-to-cycle, then repeatability will be maintained. The use of a thin elastomer between the applied force and the FSR can help absorb error from inconsistent force distributions.

- Keep the actuator area, shape, and compliance constant. Charges in these parameters significantly alter the response characteristic of a given sensor. Any test, mock-up, or evaluation conditions should be closely

matched to the final use conditions. The greater the cycle-to-cycle consistency of these parameters, the greater the device repeatability. In human interface applications where a finger is the mode of actuation, perfect control of these parameters is not generally possible. However, human force sensing is somewhat inaccurate; it is rarely sensitive enough to detect differences of less than ± 50%.

- Control actuator placement. In cases where the actuator is to be smaller than the FSR active area, cycle-to-cycle consistency of actuator placement is necessary. (Caution: FSR layers are held together by an adhesive that surrounds the electrically active areas. If force is applied over an area which includes the adhesive, the resulting response characteristic will be drastically altered.) In an extreme case (e.g., a large, flat, hard actuator that bridges the bordering adhesive), the adhesive can present FSR actuation

- Keep actuation cycle time consistent. Because of the time dependence of the FSR resistance to an applied force, it is important when characterizing the sensor system to assure that increasing loads (e.g. force ramps) are applied at consistent rates (cycle-to-cycle). Likewise, static force measurements must take into account FSR mechanical setting time. This time is dependent on the mechanics of actuation and the amount of force applied and is usually on the order of seconds.

Develop a Nominal Voltage Curve and Error Spread

When a repeatable and reproducible system has been established, data from a group of FSR parts can be collected. Test several FSR parts in the system. Record the output voltage at various pre-selected force points throughout the range of interest. Once a family of curves is obtained, a nominal force vs. output voltage curve and the total force accuracy of the system can be determined.

Use Part Calibration if Greater Accuracy is Required

For applications requiring the highest obtainable force accuracy, part calibration will be necessary. Two methods can be utilized: gain and offset trimming, and curve fitting.

- Gain and offset trimming can be used as a simple method of calibration. The reference voltage and feedback resistor of the current-to-voltage converter are adjusted for each FSR to pull their responses closer to the nominal curve.

- Curve fitting is the most complete calibration method. A parametric curve fit is done for the nominal curve of a set of FSR devices, and the resultant equation is stored for future use. Fit parameters are then established for each individual FSR (or sending element in an array) in the set. These parameters, along with the measured sensor resistance (or voltage), are inserted into the equation to obtain the force reading. If needed, temperature compensation can also be included in the equation.

FSR Usage Tips - Do's and Dont's

- Do, if possible, use a firm, flat and smooth mounting surface.

- Do be careful if applying FSR devices to curved surfaces. Pre-loading of the device can occur as the two opposed layers are forced into contact by the bending tension. The device will still function, but the dynamic range may be reduced and resistance drift could occur. The degree of curvature over which an FSR can be bent is a function of the size of the active area. The smaller the active area, the less effect a given curvature will have on the FSR’s response.

- Do avoid air bubbles and contamination when laminating the FSR to any surface. Use only thin, uniform adhesives, such as Scotch® brand double-sided laminating adhesives. Cover the entire surface of the sensor.

- Do be careful of kinks or dents in active areas. They can cause false triggering of the sensors.

- Do protect the device from sharp objects. Use an overlay, such as a polycarbonate film or an elastomer, to prevent gouging of the FSR device.

- Do use soft rubber or a spring as part of the actuator in designs requiring some travel.

- Do not kink or crease the tail of the FSR device if you are bending it; this can cause breaks in the printed silver traces. The smallest suggested bend radius for the tails of evaluation parts is about 0.1” [2.5 mm]. In custom sensor designs, tails have been made that bend over radii of 0.03” (0.8 mm]. Also, be careful if bending the tail near the active area. This can cause stress on the active area and may result in pre-loading and false readings.

- Do not block the vent. FSR devices typically have an air vent that runs from the open active area down the length of the tail and out to the atmosphere. This vent assures pressure equilibrium with the environment, as well as allowing even loading and unloading of the device. Blocking this vent could cause FSRs to respond to any actuation in a non-repeatable manner. Also note, that if the device is to be used in a pressure chamber, the vented end will need to be kept vented to the outside of the chamber. This allows for the measurement of the differential pressure.

- Do not solder directly to the exposed silver traces. With flexible substrates, the solder joint will not hold and the substrate can easily melt and distort during the soldering. Use Interlink Electronics’ standard connection techniques, such as solderable tabs, housed female contacts, Z-axis conductive tapes, or ZIF (zero insertion force) style connectors.

- Do not use cyanoacrylate adhesives (e.g. Krazy Glue®) and solder flux removing agents. These degrade the substrate and can lead to cracking.

- Do not apply excessive shear force. This can cause delamination of the layers.

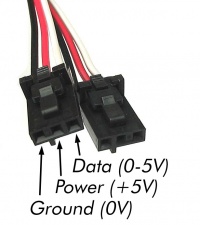

Phidget Cable

The Phidget Cable is a 3-pin, 0.100 inch pitch locking connector. Pictured here is a plug with the connections labelled. The connectors are commonly available - refer to the Analog Input Primer for manufacturer part numbers.

What to do Next

- Programming Languages - Find your preferred programming language here and learn how to write your own code with Phidgets!

- Phidget Programming Basics - Once you have set up Phidgets to work with your programming environment, we recommend you read our page on to learn the fundamentals of programming with Phidgets.